Our Services

We deliver comprehensive engineering solutions with a focus on innovation, quality, and client success. Discover how we work and what makes us different.

Two ways to work with us

Projects

We deliver tailored engineering solutions that address challenges in mechanical engineering, structural dynamics, vibration analysis, and mechatronic systems. From improving machine performance to revealing deeper insights into system dynamics, our projects accelerate your development cycle, validate critical components and help you clearly understand real-world operational behaviour.

- •Model order reduction for large-scale FE models

- •Experimental modal analysis and system identification

- •Controller design and mechatronic optimization

- •Custom simulation tool development and automation

Courses

We offer practical engineering courses and workshops that provide a comprehensive overview of state-of-the-art methods and technologies. Each program focuses on explaining the principles, strengths, limitations and implementation approaches of modern techniques, giving participants the understanding and confidence to navigate complex engineering challenges and explore innovative approaches within their field.

- •Customized workshops for engineering teams

- •Hands-on courses in dynamics and control systems

- •Academic lectures on advanced modeling techniques

- •On-site and remote delivery options available

Our Core Engineering Expertise

Numerical Methods

Our numerical workflows integrate advanced modeling and solving strategies, co-simulation approaches, and systematic validation procedures to capture complex physical interactions with high accuracy. This enables consistent performance assessment across operating conditions and supports informed decisions in design, optimization, and model selection.

Model Reduction Techniques

- •Model-, simulation-, and experiment-based reduction

- •Nonlinear, hyper-reduction, and parametric model reduction

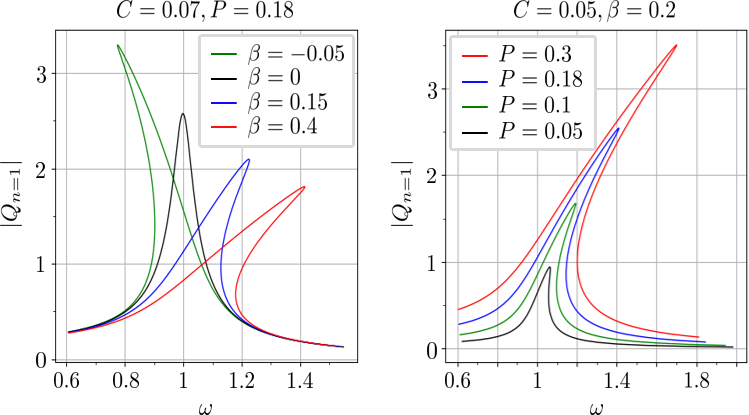

Nonlinear & Contact Dynamics

- •Joint and interface dynamics

- •Implicit & explicit simulations

- •Quasi-static strategies

- •Steady-state solutions (Harmonic Balance & Shooting methods)

Finite Element & Multibody Dynamics

- •FEM for structural dynamics, rotordynamics, and multi-physics

- •Rigid and flexible multibody dynamics

- •Co-simulation with commercial tools

- •Parameter & structural optimization

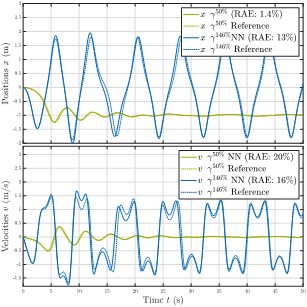

Data-Driven Modeling

- •Identification of unknown nonlinear dynamics

- •Neural-network-based reduction of high-fidelity simulations

- •Integration of measurement-based models with MBS/FEM simulations

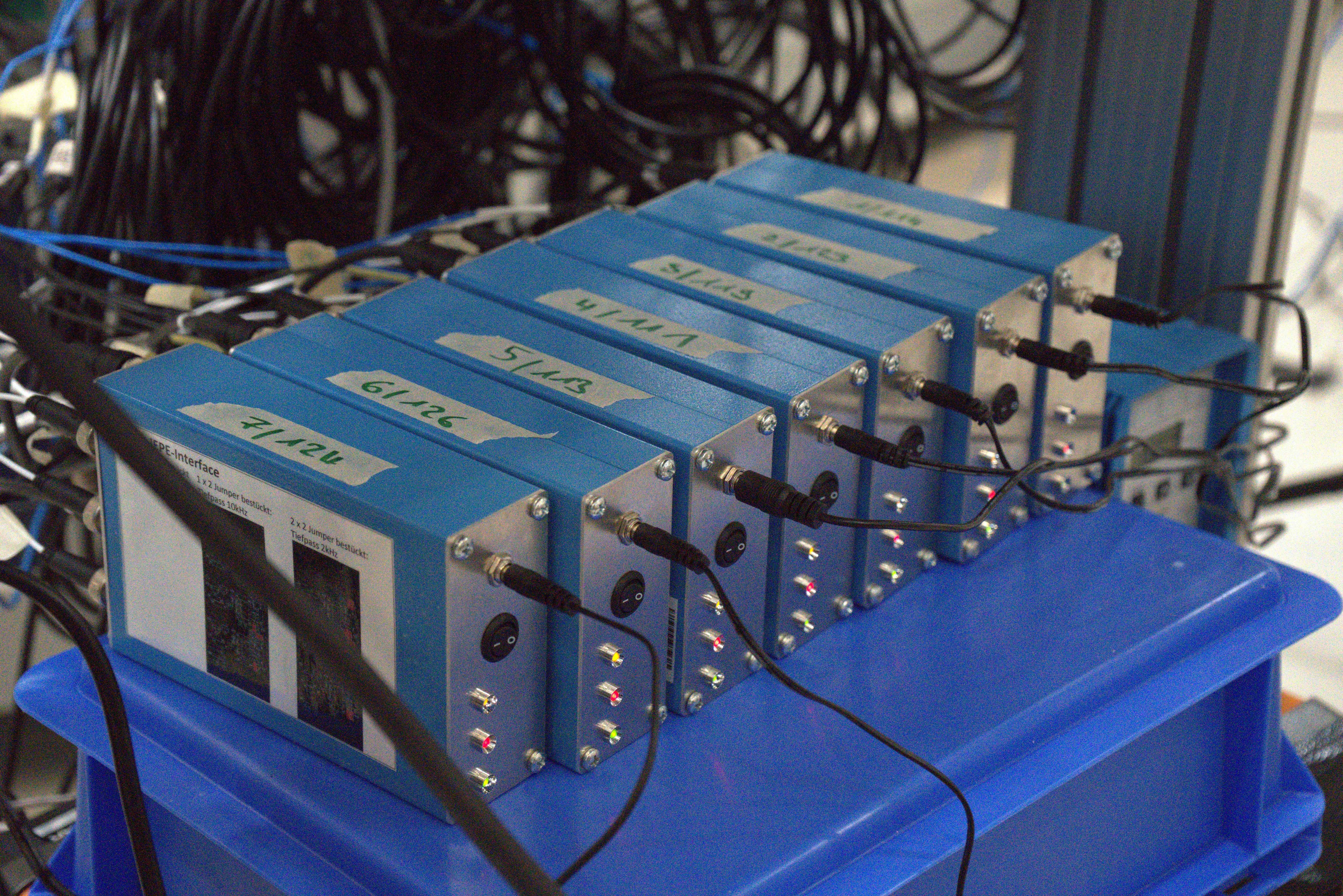

Experimental Strategies

Our experimental work ranges from precise laboratory setups to full-scale industrial testing, using advanced sensor systems and data acquisition techniques to capture dynamic behavior, validate numerical models, and identify key parameters for performance optimization.

Experimental Identification Techniques

- •Joint identification

- •Nonlinearity detection and characterization

- •Material characterization

Substructuring & Transfer-Path Analysis

- •Experimental dynamic substructuring

- •Source characterization and transfer-path analysis

- •Hybrid modeling and model mixing/expansion

Vibration Measurements

- •Spectrum analysis

- •Modal and operational testing

- •Structural health monitoring

Advanced Measuring Techniques

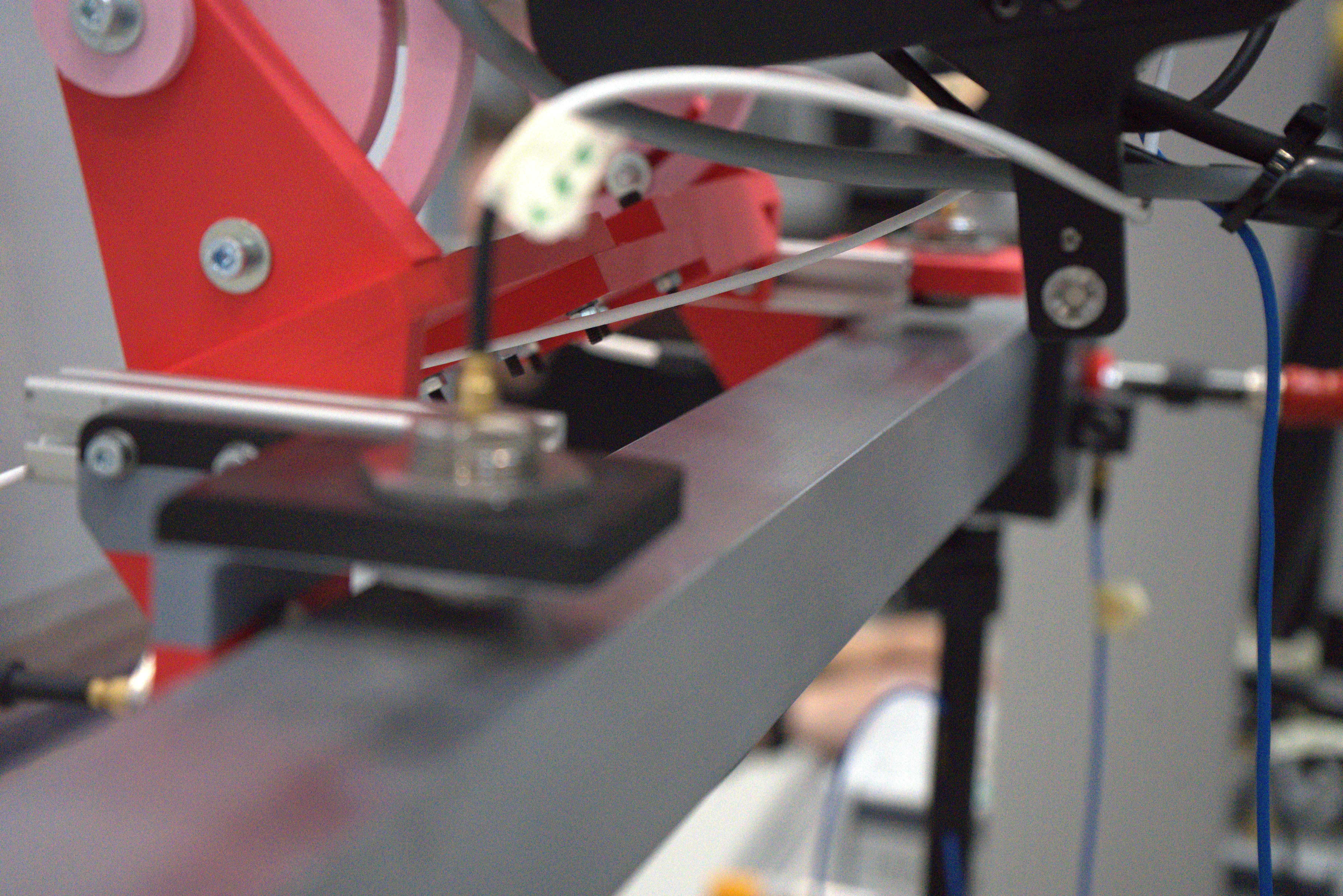

- •High-speed camera and laser vibrometry

- •Motion magnification

- •Automated impact testing

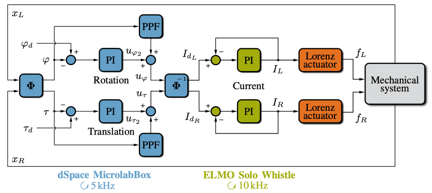

Mechatronics

Our development process integrates algorithm design, system identification, hardware-in-the-loop validation, and controller tuning to ensure reliable operation across diverse operating conditions. This systematic approach allows us to refine dynamic performance early in the development cycle and deliver mechatronic solutions tailored to demanding applications.

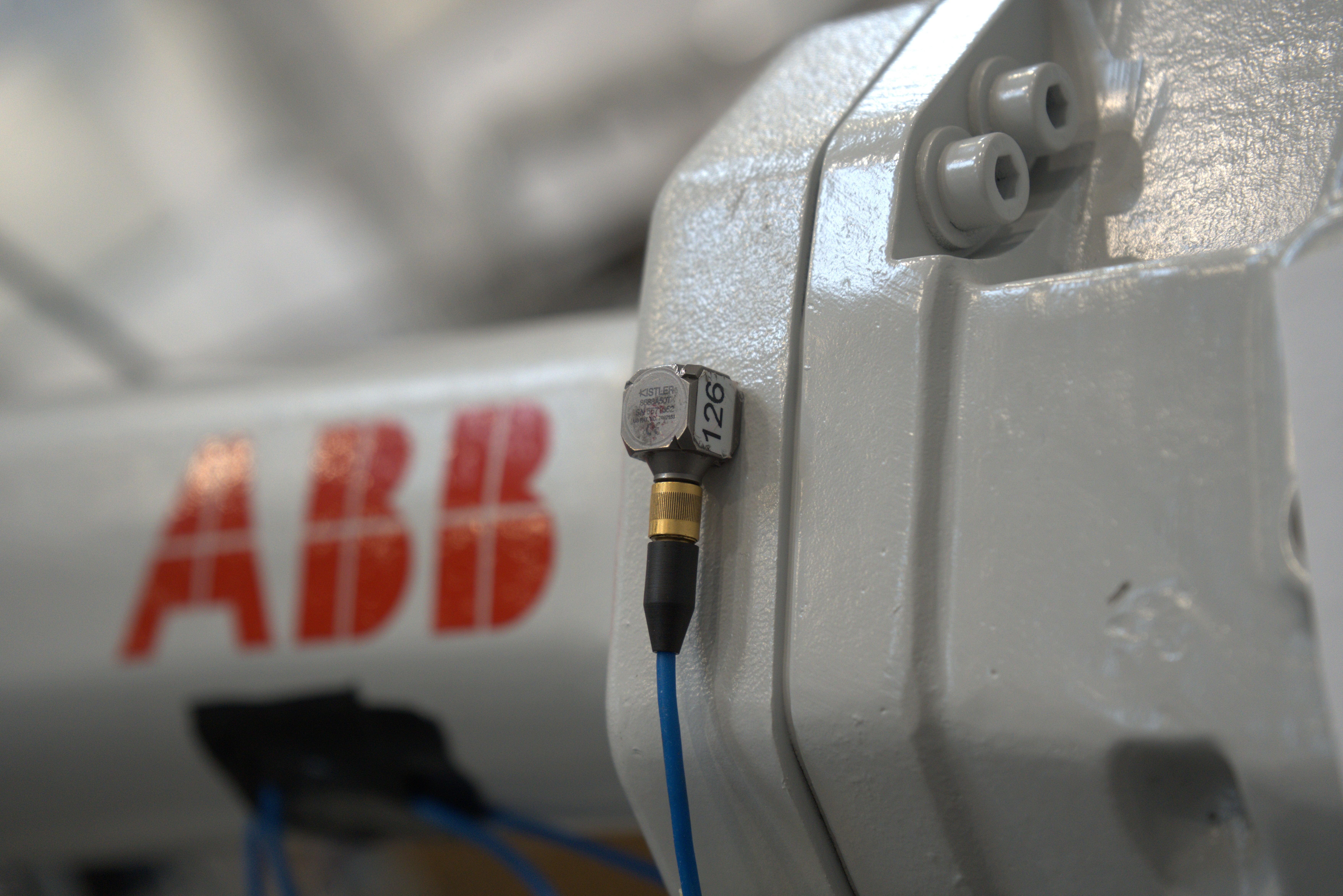

Applied Robotics

- •Tuning of assembly processes

- •Motion-planning for complex multi-objective manipulators

- •Safe collaborative robotics

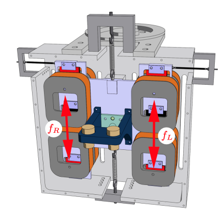

Custom Actuator Designing

- •Thermal-management solutions

- •High-precision and high-bandwidth motion solutions

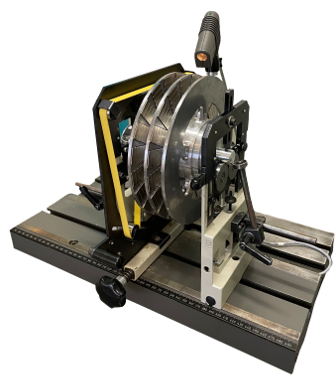

Mechatronic Prototype Development

- •Manufacturing, assembly, and programming of prototypes

- •Hardware testing and design optimization

Control System Optimization

- •Model-based control strategies

- •Virtual testing of controllers

- •Sensor fusion and state-observation for controller performance

Project Collaboration

We develop, evaluate, and model advanced engineering and mechatronic systems using advanced simulations, experimental testing, and intelligent control strategies. Our work emphasizes robust, automated engineering procedures that go beyond standard commercial tools.

We partner with clients in automotive, robotics, aerospace, and other high-tech industries to solve complex challenges. From optimizing existing systems to creating new solutions, we focus on measurable performance gains and reliable real-world outcomes.

Exploration & Feasibility Assessment

We first assess your engineering needs and challenges, evaluating suitable modern methods and highlighting opportunities to improve system performance within your organization.

Pilot Implementation on Your Use Case

We select one of the identified methods and apply it to a concrete use case within your company. Through targeted simulations, experiments or control strategies, we demonstrate the effectiveness and practical value of the chosen approach.

Development of Complete Solutions and Custom Software

Based on the insights gained from the pilot phase, we design and deliver full-scale engineering solutions or bespoke software tools tailored to your processes, enabling long-term, efficient and scalable performance improvements.

Project Highlights

Contactless Motion Analysis

Challenge

Classical accelerometer-based structural-dynamics analysis has shown limitations for complex systems.

Solution

- Full-field sensing: we measured the whole system without knowing a priori which components dominate the dynamics.

- Contactless acquisition: we avoided influencing the system while accelerating measurement setup.

- Clear visualization: we enabled trustworthy interpretable qualitative analysis of motion and component interaction.

Outcome

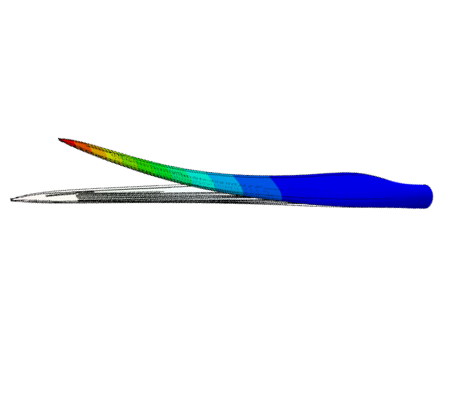

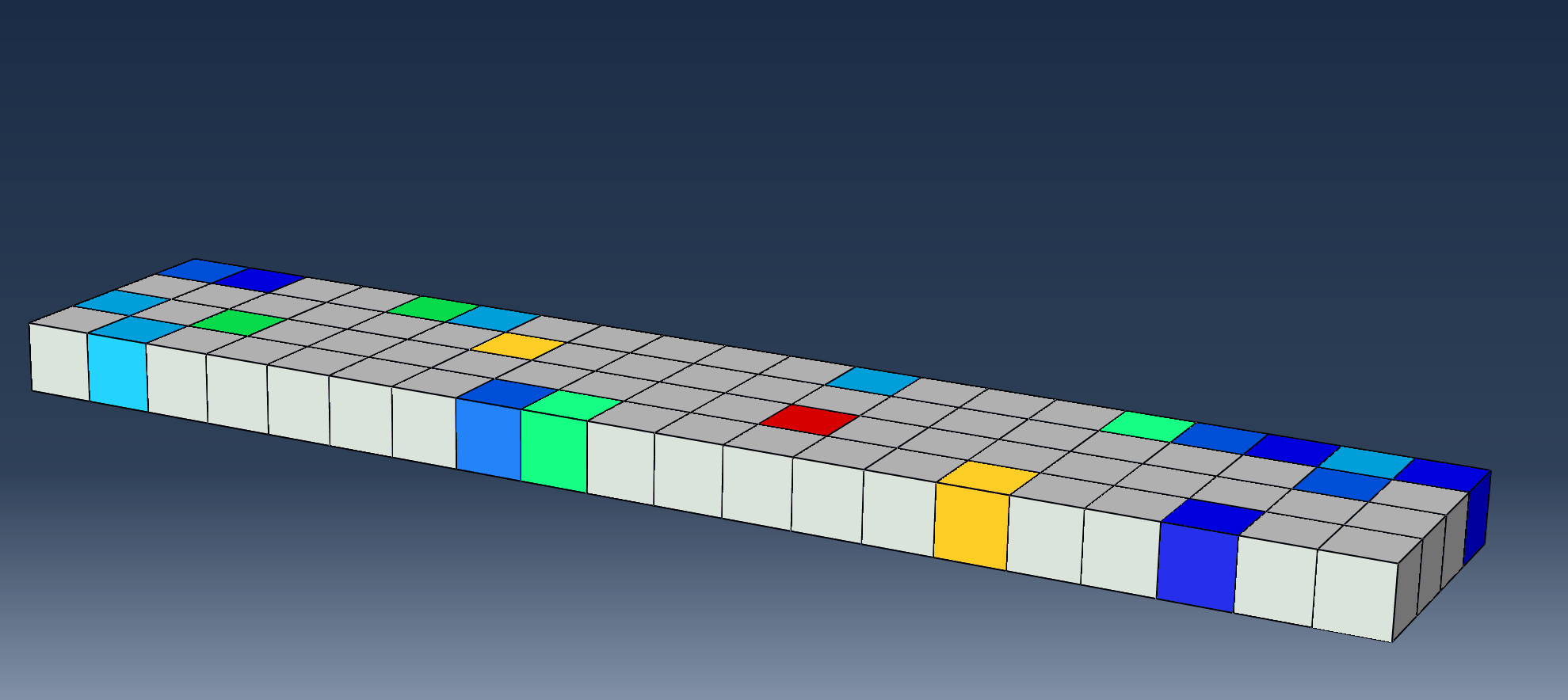

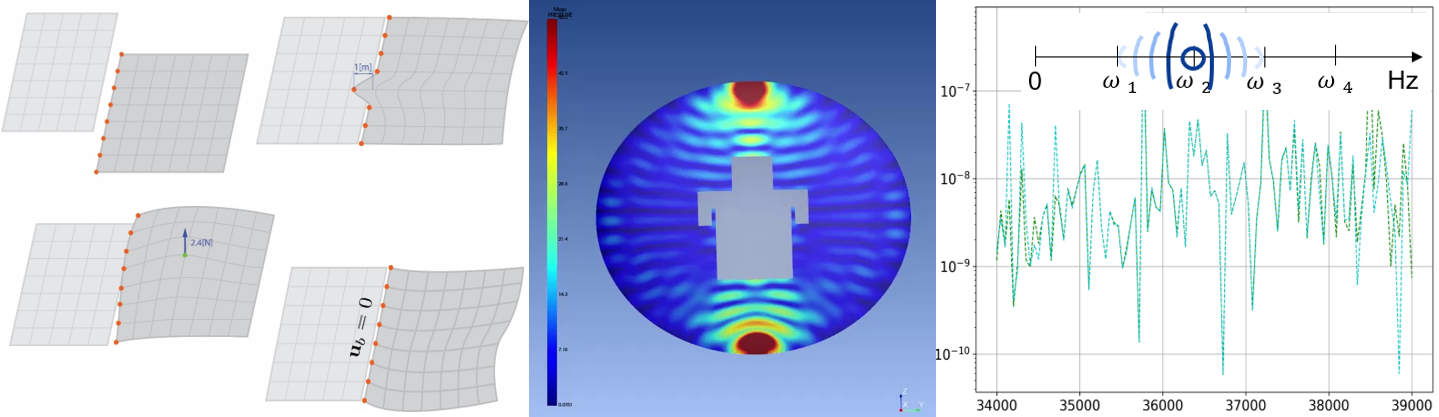

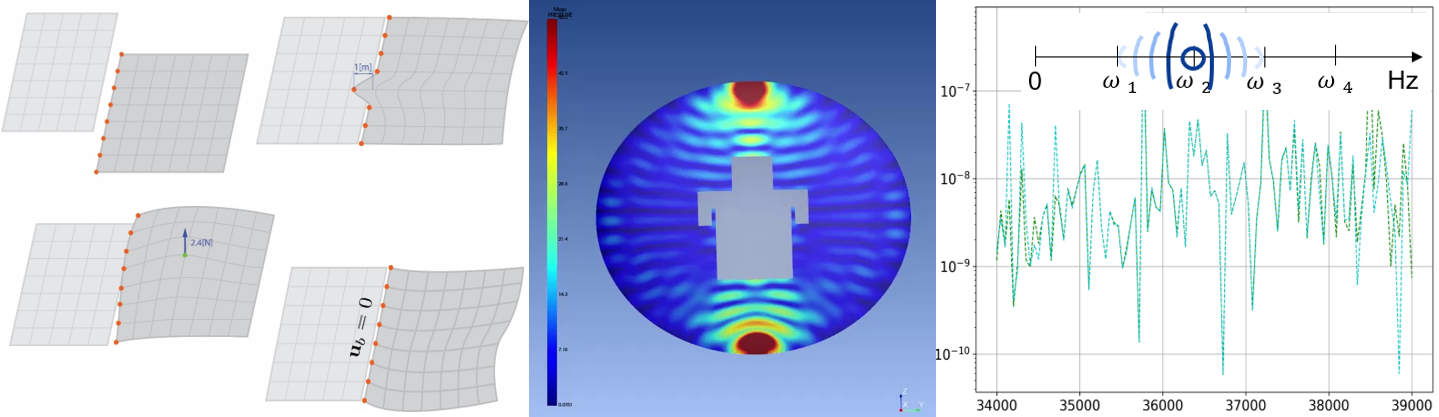

Reduced-Order Simulation

Challenge

Large multi-physics FE models can be too computationally expensive for design optimization and fast parametric studies.

Solution

- Modular reduction framework: we built a component-based model order reduction and substructuring workflow, enabling fast updates by reducing and re-analyzing only the components that change.

- Industry-friendly workflow: we implemented a flexible Python-based toolchain with interfaces to commercial FE models for efficient integration into existing simulation workflows.

Outcome

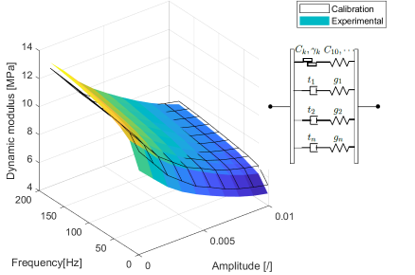

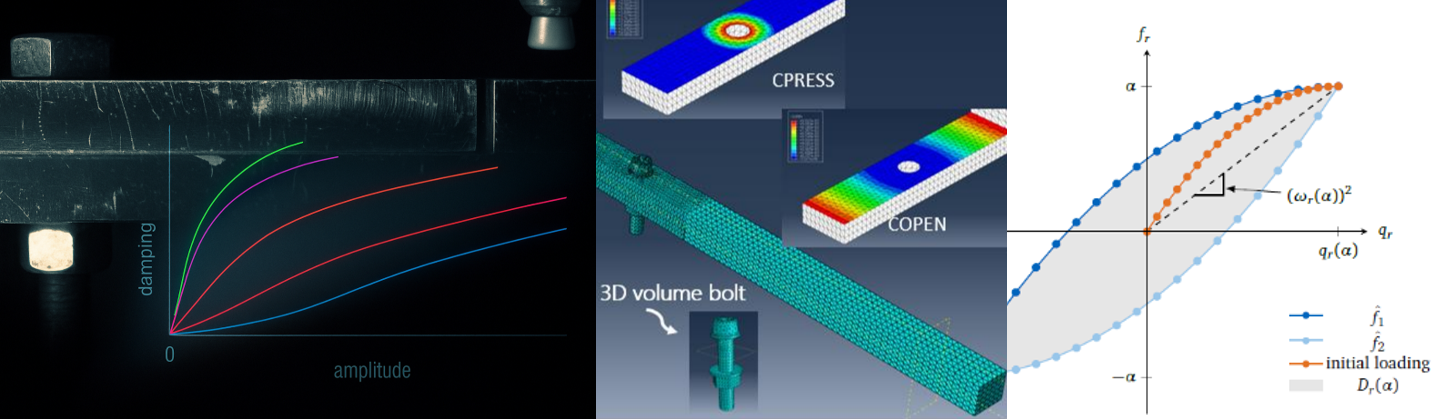

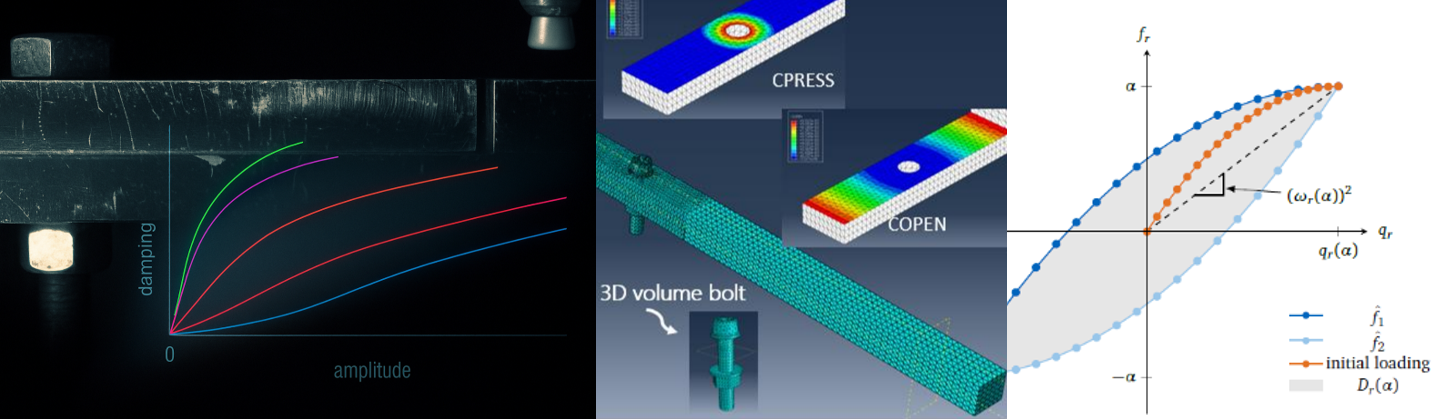

Non-linear Component Testing

Challenge

Some components exhibit non-linear behavior under real loads, which can shift resonance behavior, cause energy dissipation and reduce predictability if treated as linear.

Solution

- Non-linearity detection and quantification: we identified when the response departs from linear behavior and how stiffness/damping evolve with amplitude and operating conditions.

- Model calibration and validation: we used measured non-linear signatures to calibrate parameters and verify that numerical models reproduce the observed behavior.

Outcome

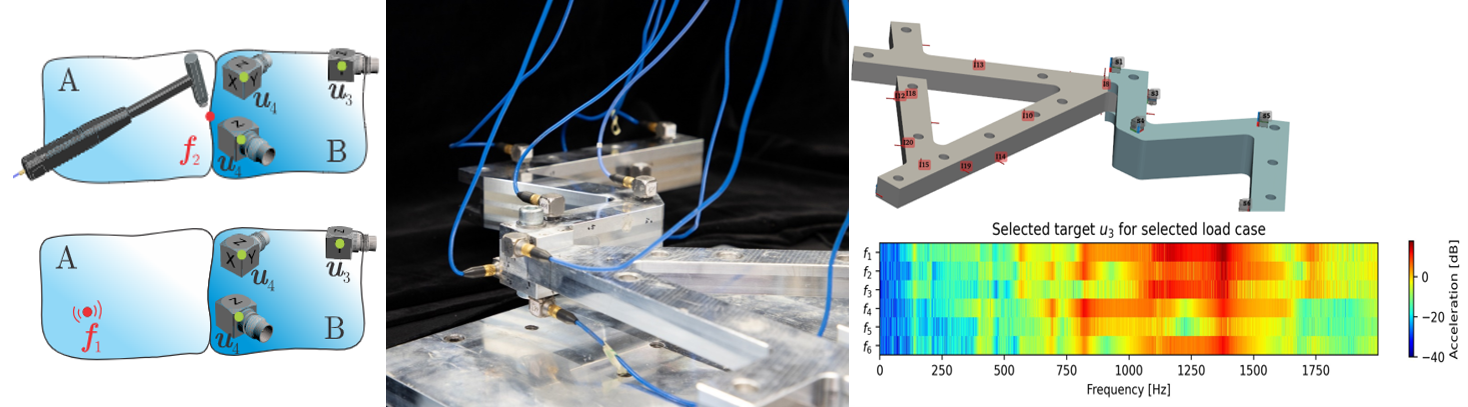

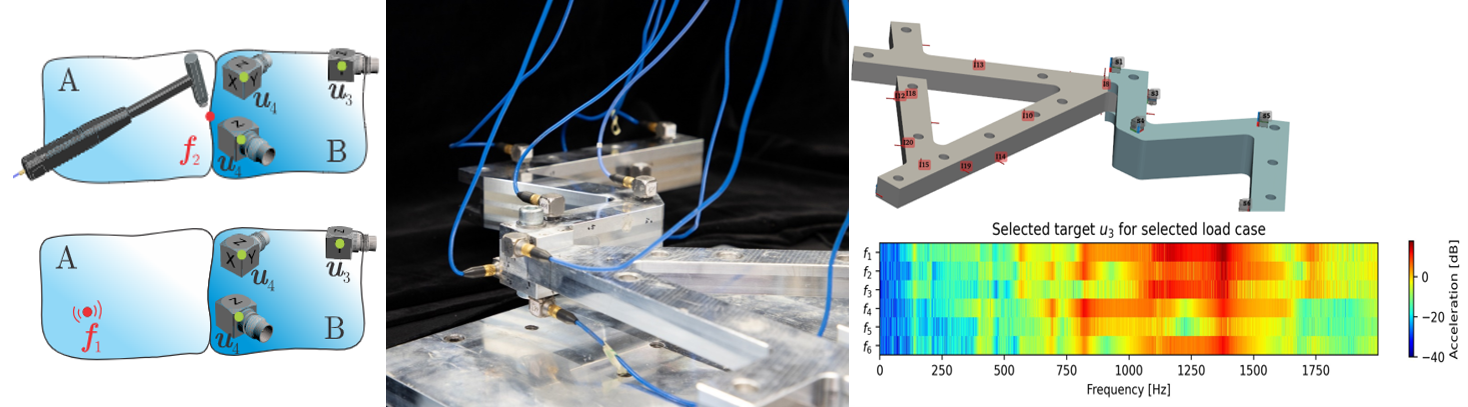

Transfer Path Analysis

Challenge

In complex machines, vibrations can travel through many connections, making it hard to see which paths actually cause the unwanted vibration at a specific component.

Solution

- Estimate operational sources: we separated and characterized the main vibration sources while the machine has been running.

- Rank transfer-paths: we identified which connections transmitted the most vibration to the target component across the frequency range of interest.

Outcome

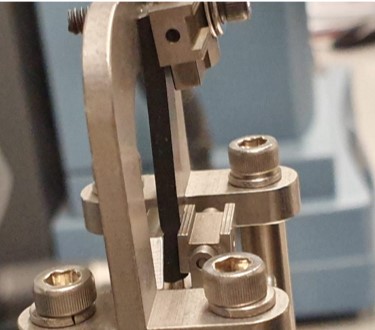

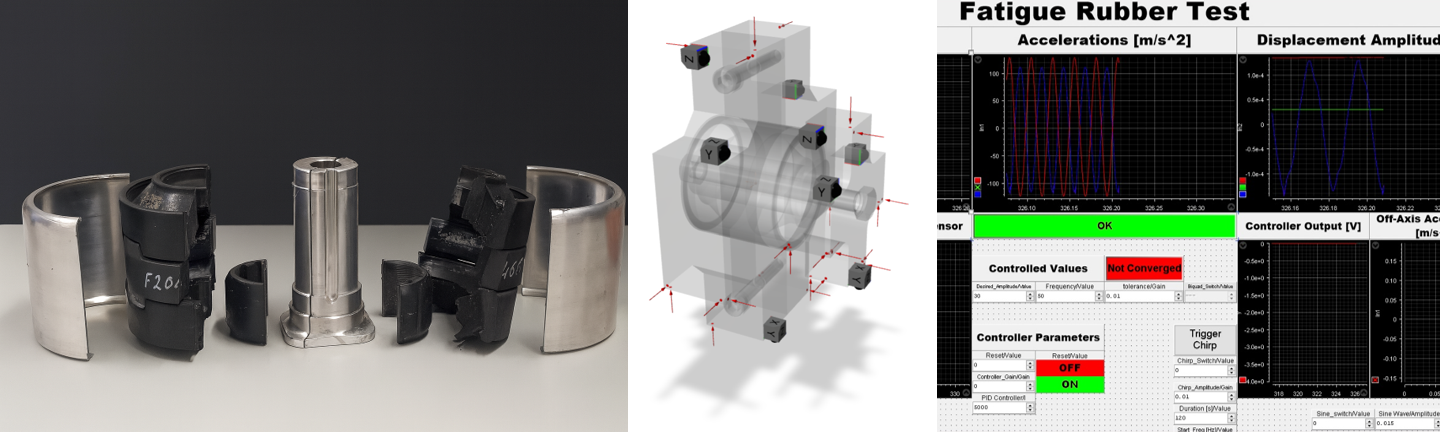

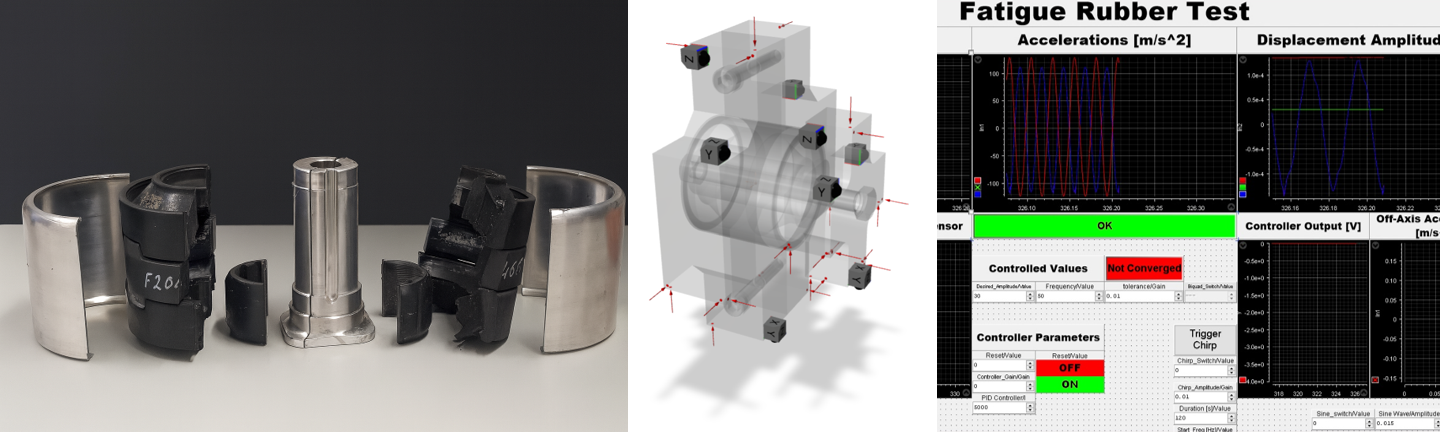

Isolation Mount Characterization

Challenge

Rubber mounts are widely used in industry for their flexibility and vibration isolation, but are difficult to model due to their complex multi-material construction and condition-dependent behavior.

Solution

- Component-level dynamics: we used impact testing with substructure decoupling to capture the mount's frequency response under realistic boundary conditions.

- Material dependencies: we tested amplitude, temperature and fatigue effects to validate the mount model and support material selection for the operating regime.

Outcome

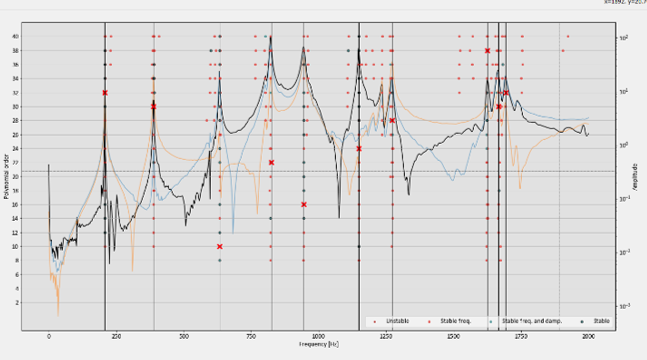

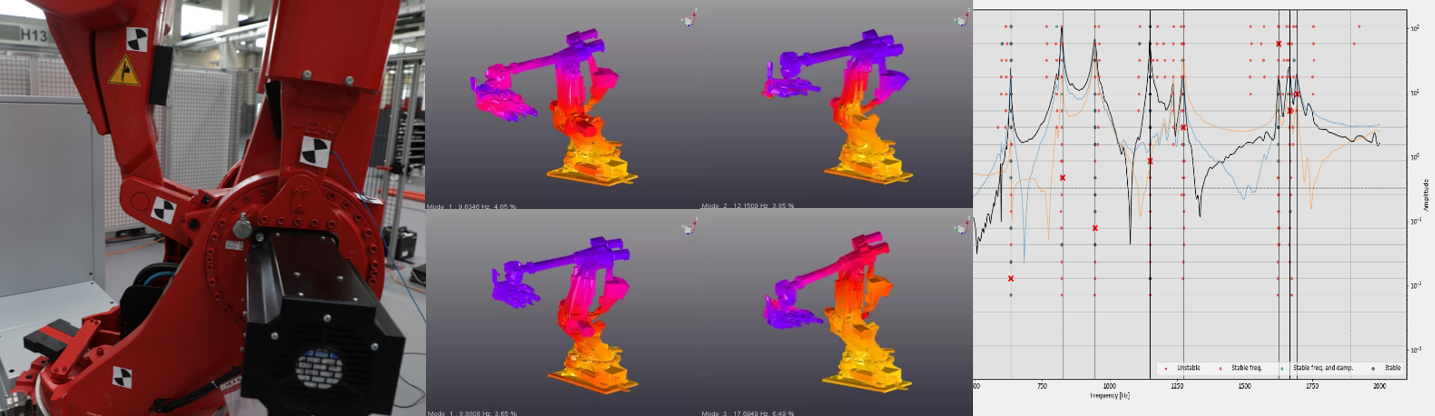

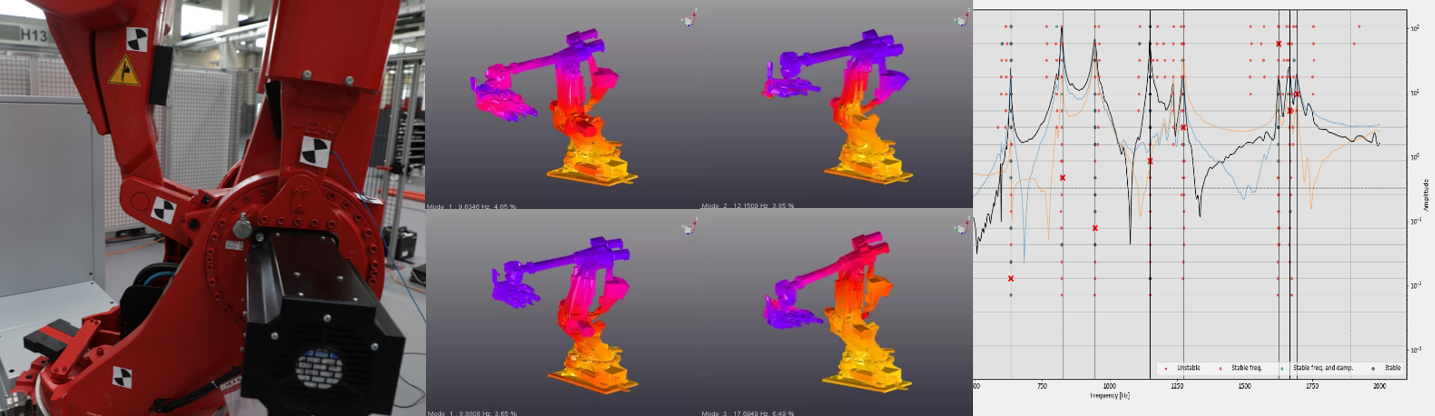

Spectrum Analysis

Challenge

Large, mechatronic systems can exhibit configuration- and operating-condition–dependent vibrations, which can make processes less accurate and less efficient.

Solution

- Frequency-response measurements: we measured frequency responses to map resonances, damping, and transfer behavior.

- Modal analysis: we carried out experimental and operational modal testing across different configurations.

- Nonlinear effects: we checked for and visualized possible nonlinear behavior under realistic operating conditions.

Outcome

Workshops & Courses

We offer specialized engineering courses that combine essential theory, modern methods, and practical insight. Participants benefit from our research and industry experience, gaining clarity on current practices and emerging trends.

Our courses range from high-level conceptual overviews to application-oriented sessions, with options for demonstrations or theory-focused learning. We offer both open courses and customized training tailored to client needs.

Course Formats

What to Expect

- •Duration:3 days (or 12-16 hours)Depending on the contentIntensive sessions or spread throughout weeks (e.g. 2 hours appointments, one/twice per week)

- •Participants:Usually up to 10 participantsDepending on the agreed configuration of the workshop

Model Reduction Techniques

An all-encompassing overview from simple linear reduction to cutting-edge parametric and nonlinear techniques.

Uncovering the full spectrum of model reduction, from simple linear methods to advanced parametric and nonlinear approaches. The workshop covers the complete workflow, modeling through solving, and clarifies distinctions between testing and numerical methods, linear and nonlinear models, and data-driven strategies. Participants will also learn how to select suitable techniques and explore the best opportunities for their application.

Download Syllabus (PDF)Experimental Identification / Vibration Analysis

A general perspective on using experimental testing to detect, identify, and model dynamical systems.

A general perspective on the use of experimental testing to detect, identify and model a dynamical system. From classical modal characterization to modern substructuring and transfer path analysis workflows for linear vibrating systems. Deep insights into testing strategies for nonlinear structural components and assemblies. Discovering the newest sensing technologies, such as cutting-edge camera-based testing. Participants will learn the basics and get into the heart of experimental identification.

Download Syllabus (PDF)Custom Workshops

We create custom tailor-made courses or workshops for your specific needs across various engineering fields.

We have expertise in a broad range of fields with teaching experience in academic and industrial environments. We are therefore happy to create custom tailor-made courses or workshops for your specific needs. Simply contact us with the details of what you are looking for.