Use Case

In complex machines, vibrations pass through multiple connections and interfaces, leading to local interface motion, relative displacements and deformation patterns that are not easily captured. This is particularly relevant in motorcycle assemblies, where compact packaging, many joints, and multiple excitation sources generate coupled operational behaviors that can be difficult to characterize comprehensively with traditional measurements. In order to optimize comfort at the passenger contact locations, a better understanding of the noise, vibration and harshness (NVH) behaviour of the motorcycle is required.

Technological Solution

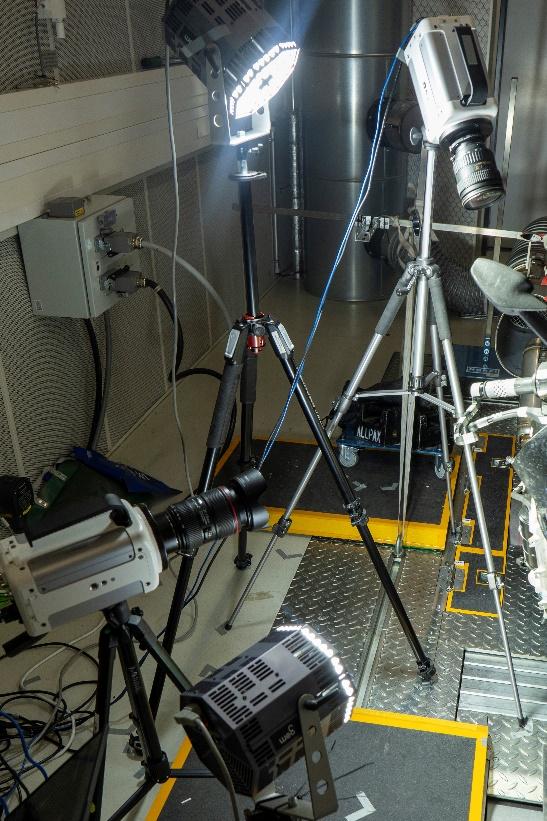

Inventum applied contactless motion analysis using optical measurement and video-based vibration processing. By leveraging motion magnification, subtle operational vibrations become visible, enabling a fast, full-field view of deformation patterns that are otherwise hard to detect.

Why it's valuable for NVH:

- Contactless, automated testing with reduced setup effort and no sensor mass loading of the structure

- Full-field visualization across entire system areas (not just single sensing points) from multiple directions (enabling 3D analysis)

- Supports evaluation, design comparison, and numerical model correlation

The cooperation progressed from controlled studies on small mechanical sub-assemblies using shaker-based testing, benchmarking the benefits versus traditional sensor-based modal approaches and cross-checking results with numerical simulations, to full vehicle application on a high-speed chassis dynamometer, across a wide operating range. This enabled targeted observation of vibration behavior of multiple components under real operating conditions. The low setup effort allowed for measurement of numerous different component variants and design iterations with direct comparison.

Outcome

The work showed how contactless motion analysis can accelerate understanding of motorcycle vibration behavior by making operational dynamics visible, measurable, and comparable.

Key benefits include:

- Faster identification of vibration-sensitive behaviors

- More informed design evaluation on selected areas of interest

Enabling:

- Improved rider comfort through vibration reduction

- Better long-term system robustness through a clearer understanding of operational deflections and component wear

This activity is part of an ongoing collaboration with BMW Motorcycle, and we look forward to further expanding and industrializing full-field, contactless NVH methods.