Transfer Path Analysis with Hilti

Use Case

In complex machines, vibrations and structure-borne noise propagate through many connections and interfaces, making it challenging to understand which paths actually drive vibration at a specific component. This is especially true for compact yet highly integrated mechatronic devices, such as high-performance power tools, where multiple internal excitations and tight packaging lead to coupled dynamics.

In these systems, significant real engineering value comes from understanding how vibration travels through the assembly, and which interfaces and joints contribute most, so design changes can be aimed at the right places to achieve the desired vibration performance.

Technological Solution

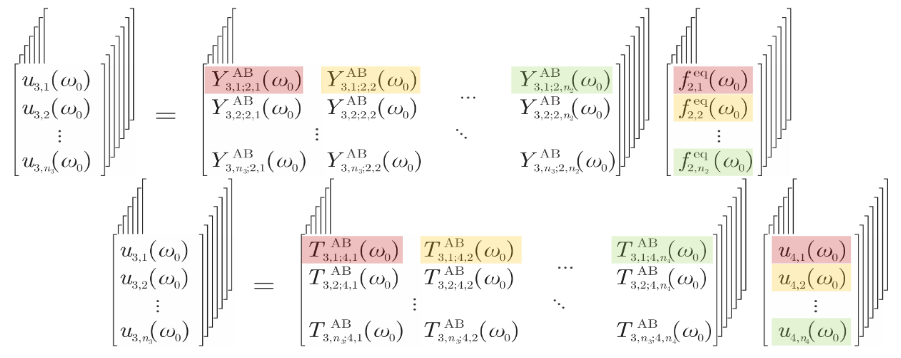

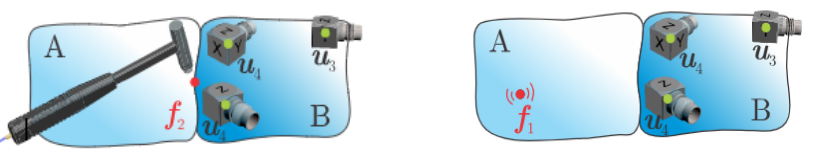

Inventum introduced and applied advanced Transfer Path Analysis strategies to experimentally characterize operational excitations and quantify how these excitations transmit through the system to a chosen receiver location.

Since multiple TPA families exist, ranging from classical to component-based and operational TPA, we covered the practical trade-offs in terms of measurement effort, assumptions, and interpretability.

Two of the main outcomes of TPA are:

- Estimate operational sources: separate and characterize the main excitation contributions while the system is running

- Rank transfer paths: identify which connections transmit the most vibration to the receiver across the relevant frequency range

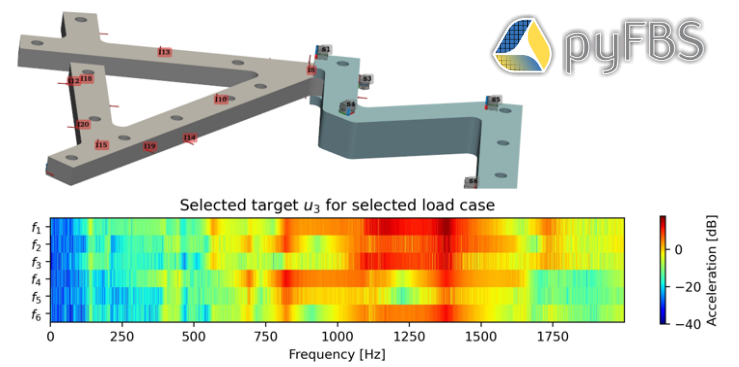

The workshop format intentionally combined "why it works" with "how to do it," highlighting typical pitfalls, good testing practices, and processing choices that matter when moving from demonstrations to real product development. In the hands-on sessions, we emphasized robust industrial workflows and implemented the methods using the open-source platform pyFBS, turning theory into repeatable practice.

By applying the techniques directly on the Hilti power tools live, case-specific processing challenges could be explored and solved.

Outcome

By applying a structured, design-of-experiments-oriented workflow on a Hilti power tool, we identified which drive-unit interfaces/joints contributed most to vibration at the targeted receiver component. We then quantified each connection's contribution by direction, enabling targeted redesign actions (e.g., interface changes, stiffness/damping adjustments, mounting concepts) rather than broad trial-and-error modifications.

Both component-based and operational TPA strategies were successfully demonstrated, showing how dominant transfer paths can be determined with different approaches depending on available measurements, constraints, and development goals.

We thank Hilti for the great collaboration and look forward to continuing our joint work on advanced vibration and NVH diagnostics.